Overview

September 2014 - March 2015

For my senior capstone project I served as technical lead on a team of 5. We were tasked with redesigning the instrument panel and rear seat of the Arctic Tern with the objectives of improving user comfort, modernizing the interior, and reducing weight. In a 20 week period, we design, built, and tested a carbon fiber instrument panel and carbon fiber rear seat. In total, we saved ~25 lbs and ensured our deliverables conformed with FAR Part 23 regulations.

Achieved

- Final weight : 8.0 lbs.

- Increased head room by 4.0 in.

- Pass. Held 1254 lbf without failure.

Specifications and Requirements

Seat must weigh less than 10.4 lbs.

Increase head room by >1.0 in.

Static Load Requirement: 1254 lbf (+4.4G * 190 lbs * 1.5 SF)

Before

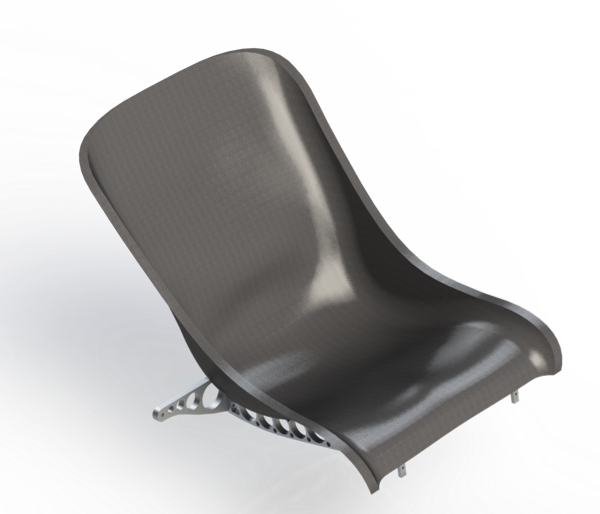

After

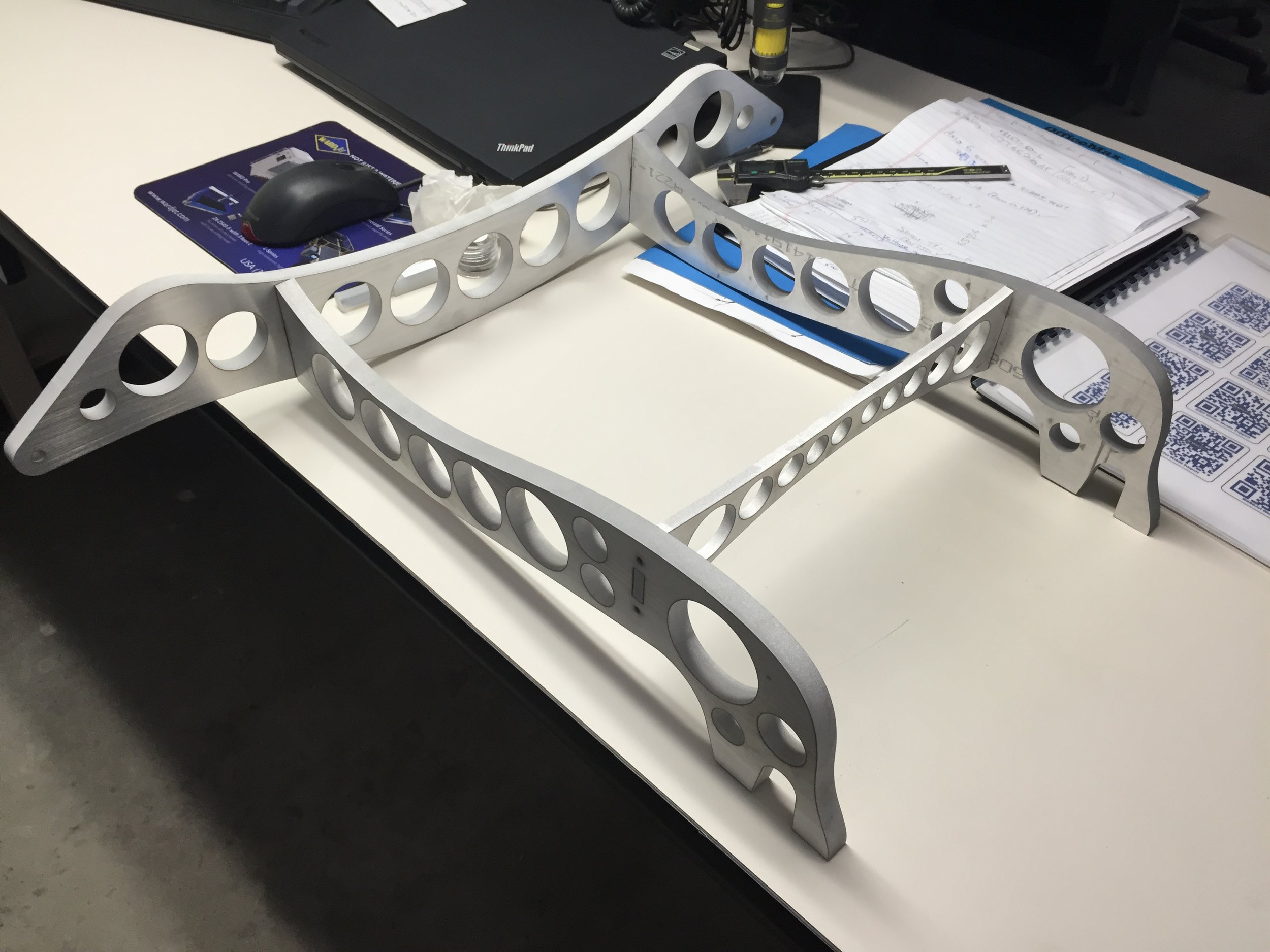

Design

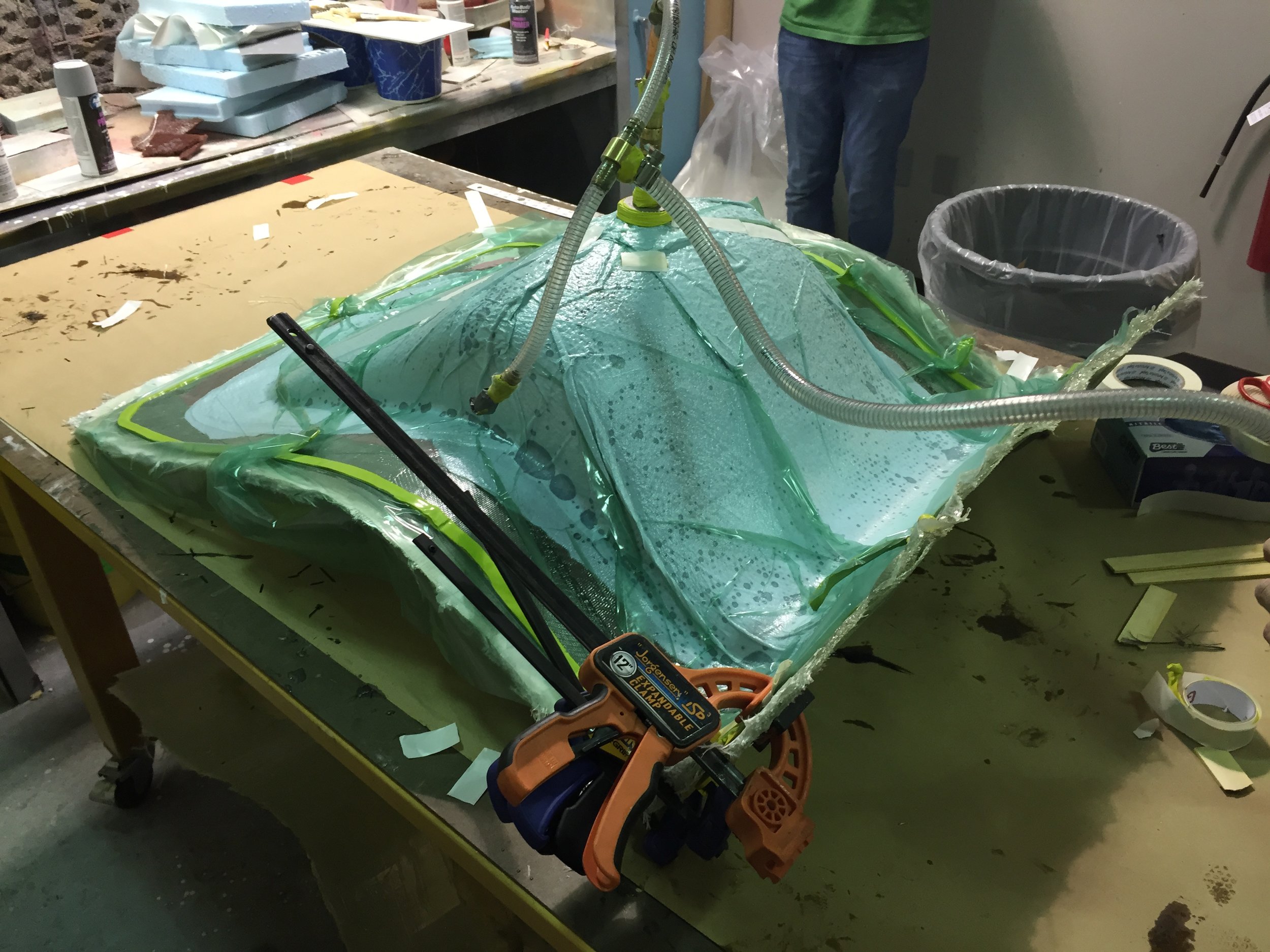

Build

Test

My Contributions:

- SolidWorks surfacing of seat geometry.

- CAD design and CAM of foam plug for mold construction.

- Helped composite fabrication of mold and final seat.

- As technical lead, I helped team through design and fabrication challenges with rear seat.