Overview: M.S. Research

M.S. Advisor: Professor Ulrike G.K. Wegst | April 2015 - August 2016

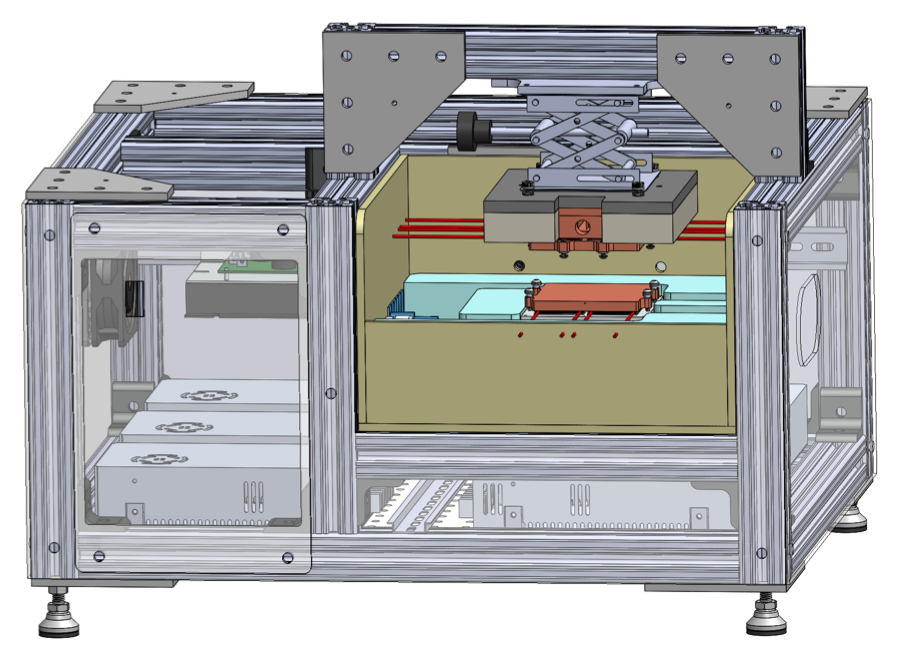

For my M.S. research, I designed, built, and tested new, multipurpose freeze casting equipment to address the current limitations in freeze casting with two main aims:

Aim 1: Enable experiments that increase the fundamental understanding of the freeze casting process.

Aim 2: Improve the manufacturing process by creating equipment capable of fabricating larger samples in new shapes.

My overarching research approach was to iterate efficiently while keeping designs and experiments simple and cost effective. The goal was to identify and tackle as many problems as possible and prototype solutions that would guide future work.

Background: Freeze Casting Process

Freeze Casting is a material processing technique that utilizes directional solidification and phase separation in solutions or slurries to fabricate microporous structures with highly aligned porosity. The process consists of three main steps: solution/slurry preparation, unidirectional solidification with a thermal gradient (freezing), and lastly sublimation of solvent.

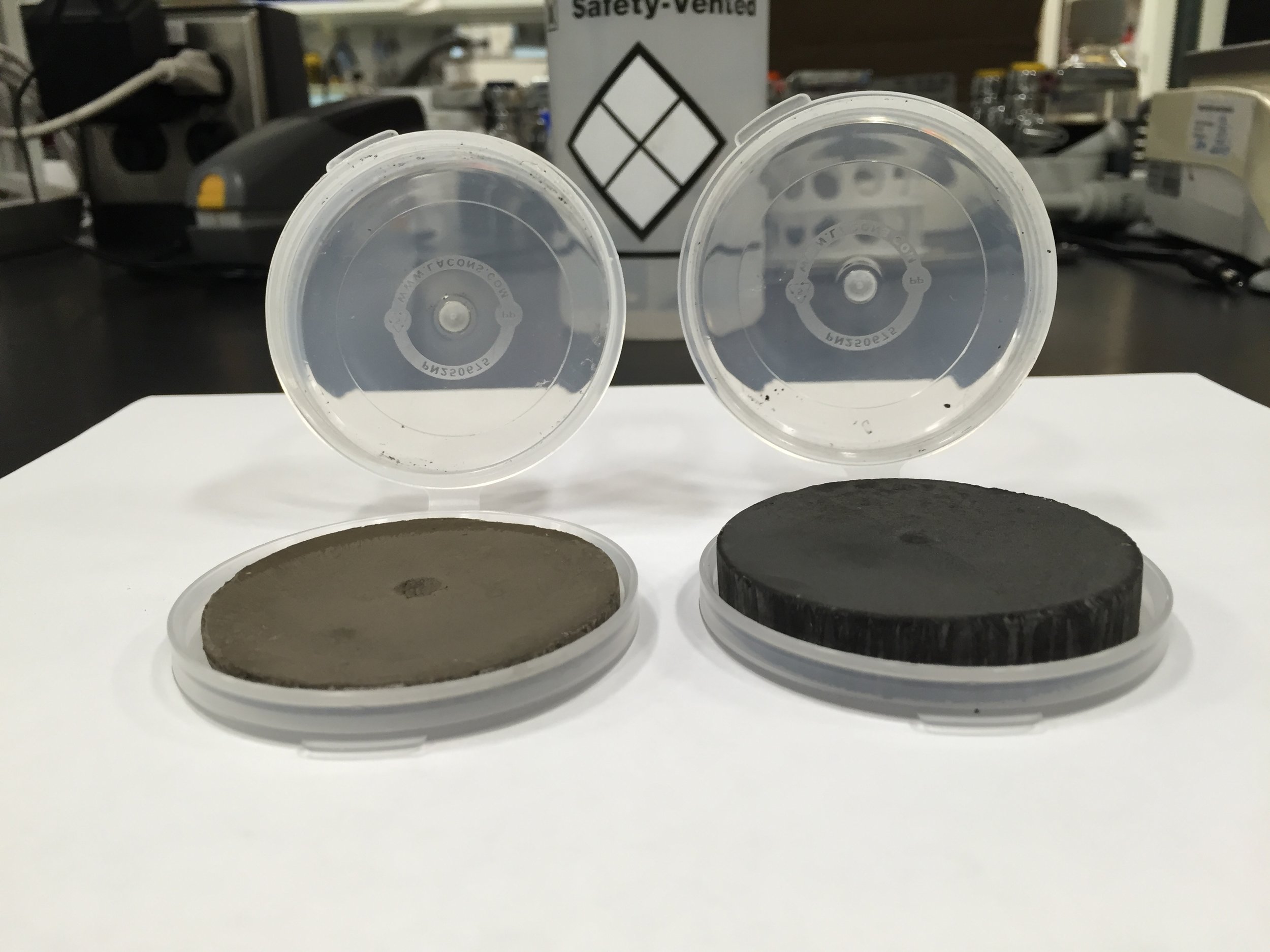

The image shows the typical microstructure of a sodium alginate freeze cast material. The polymer solution was unidirectionally solidified and then the ice was sublimated away, leaving the resulting structure.

Schematic of a typical single side freeze caster and freezing process. The slurry is poured into a PTFE mold with polished copper bottom. PID controlled resistive heaters control temperature. The copper rod is immersed in liquid nitrogen and acts as a heat sink. (b) Controlled freezing results in the formation of lamellar ice crystals that expel the particles and/or solutes and are concentrated in the space between the crystals. (c) The crystals template the structure and after sublimation the resulting structure is highly-aligned and porous, as the SEM images show. Reproduced from U. G. K. Wegst, H. Bai, E. Saiz, A. P. Tomsia, and R. O. Ritchie, "Bioinspired structural materials," Nat Mater, vol. 14, pp. 23-36, 01//print 2015.

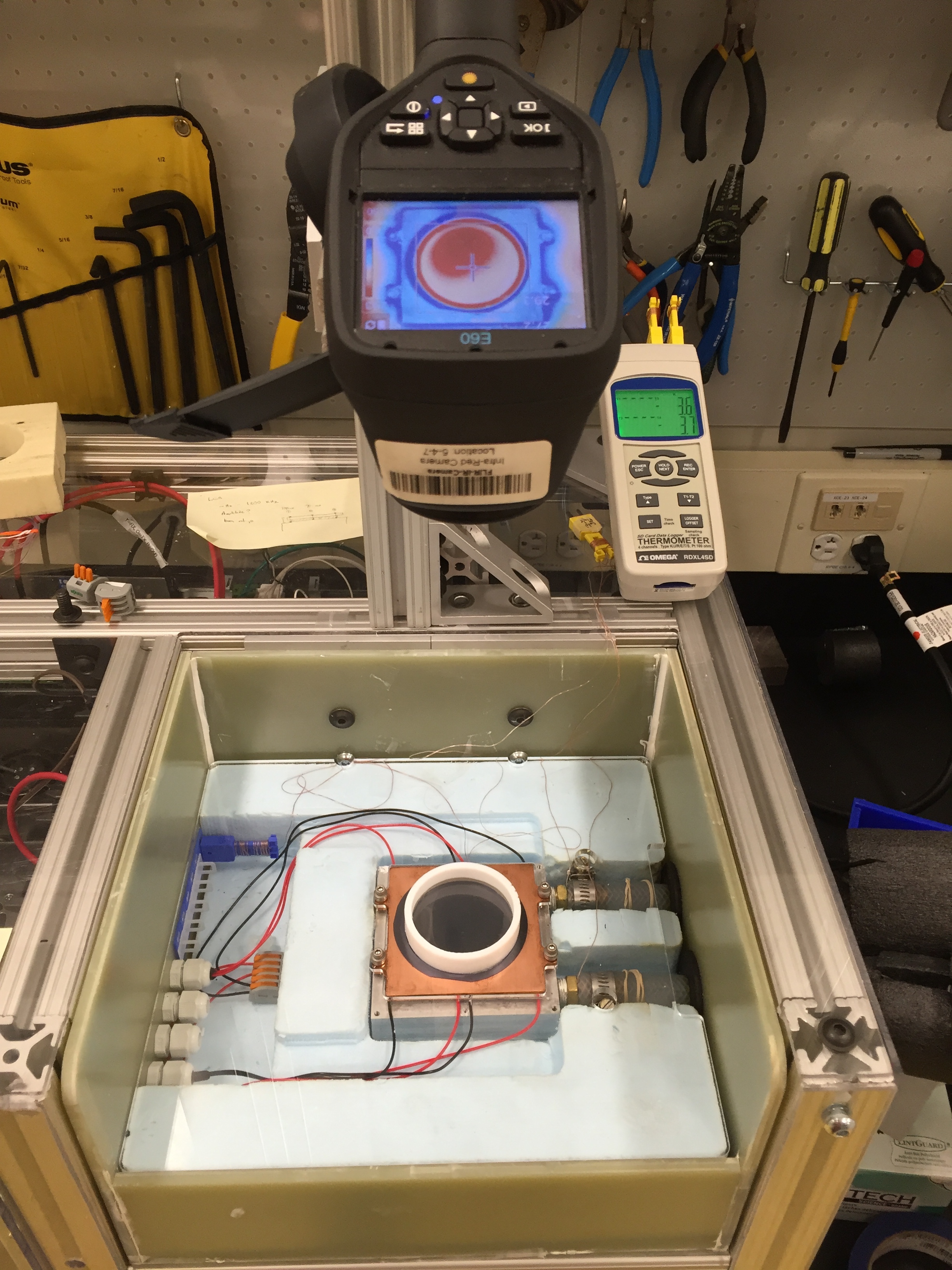

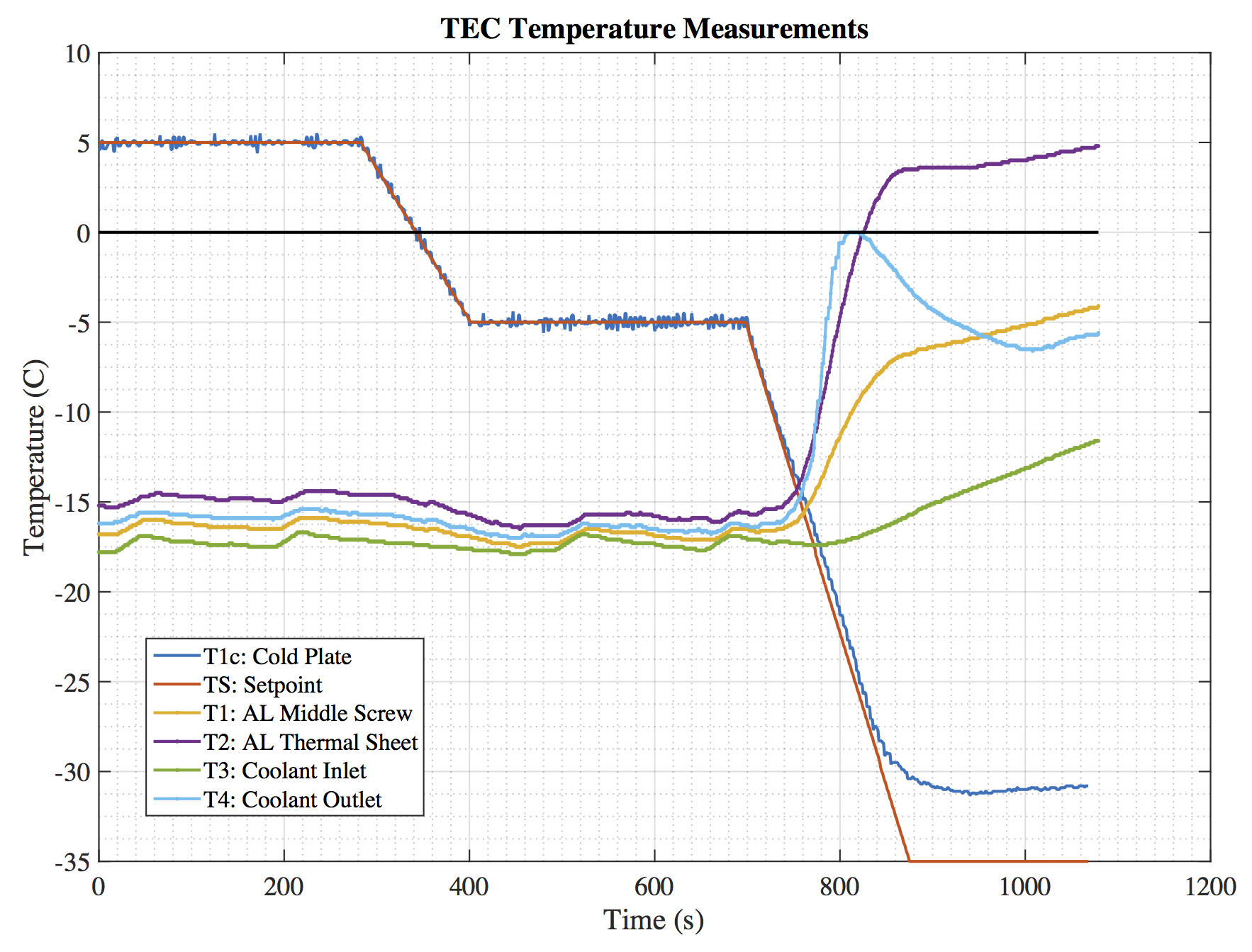

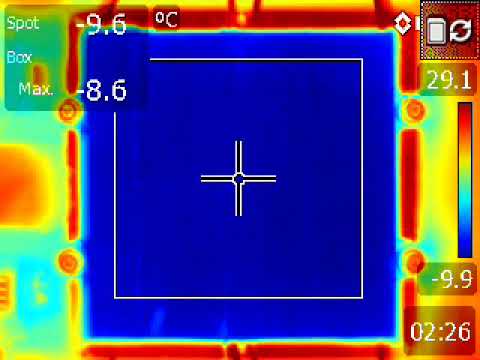

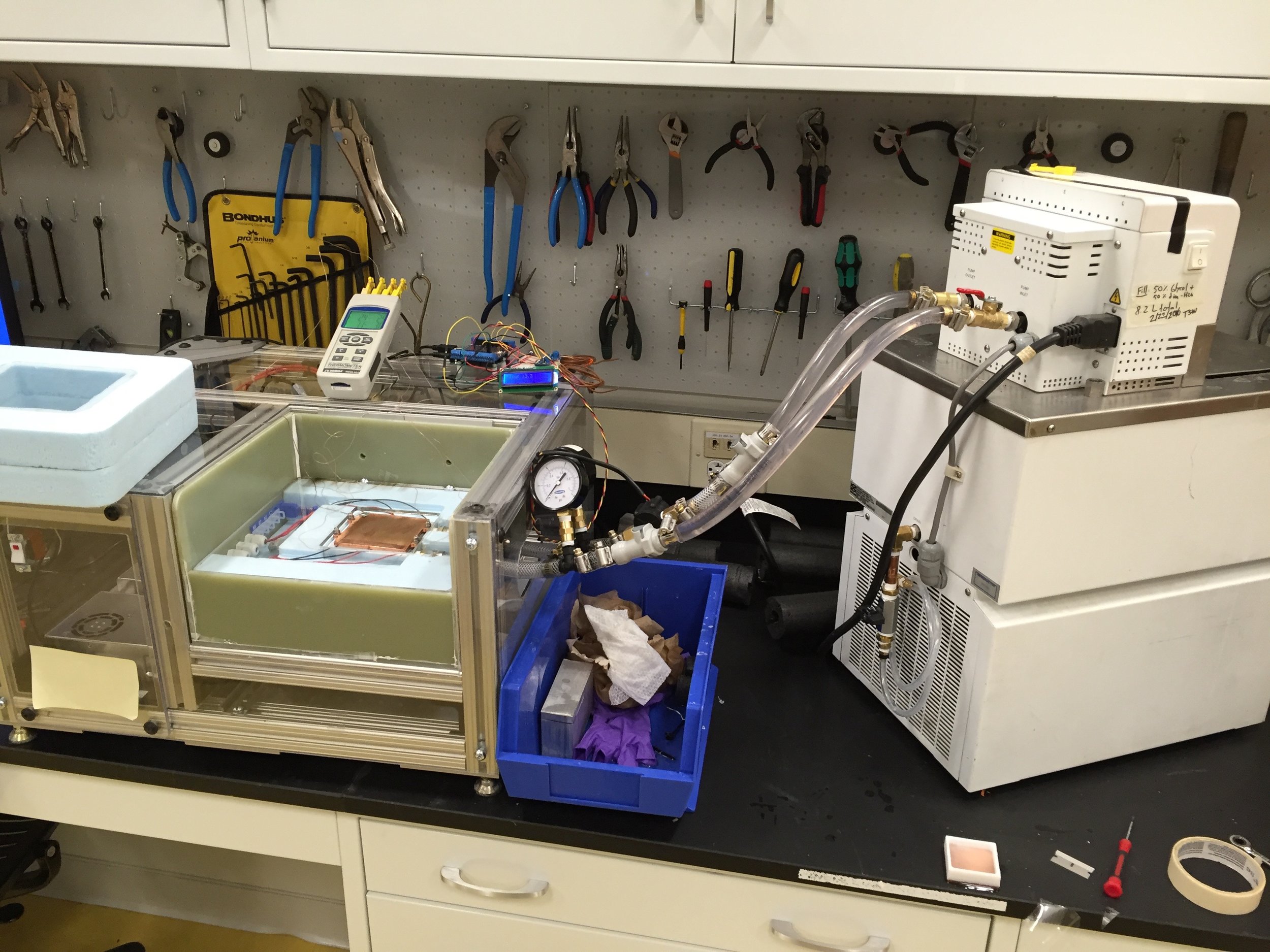

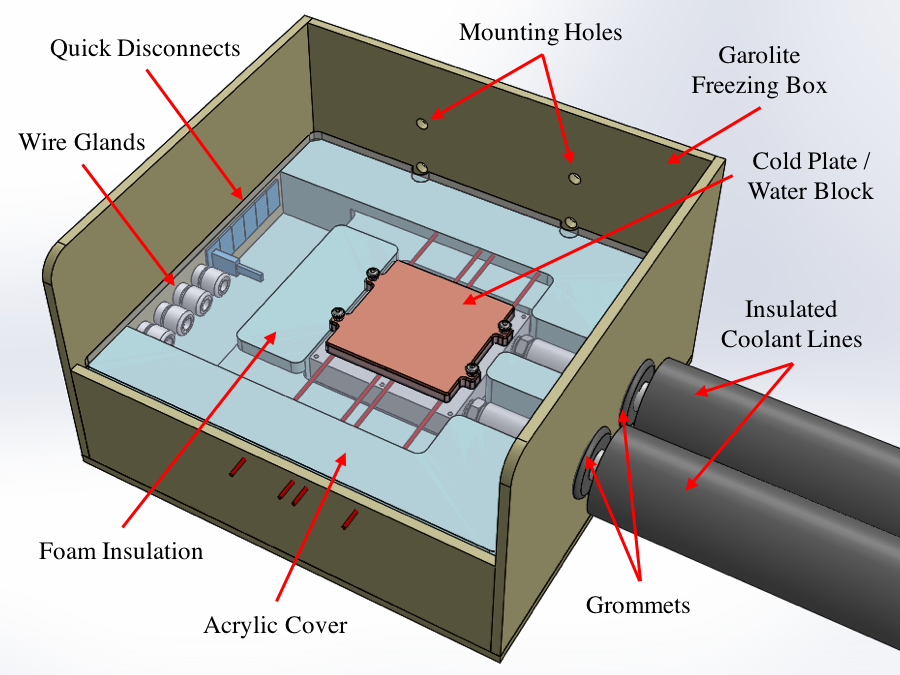

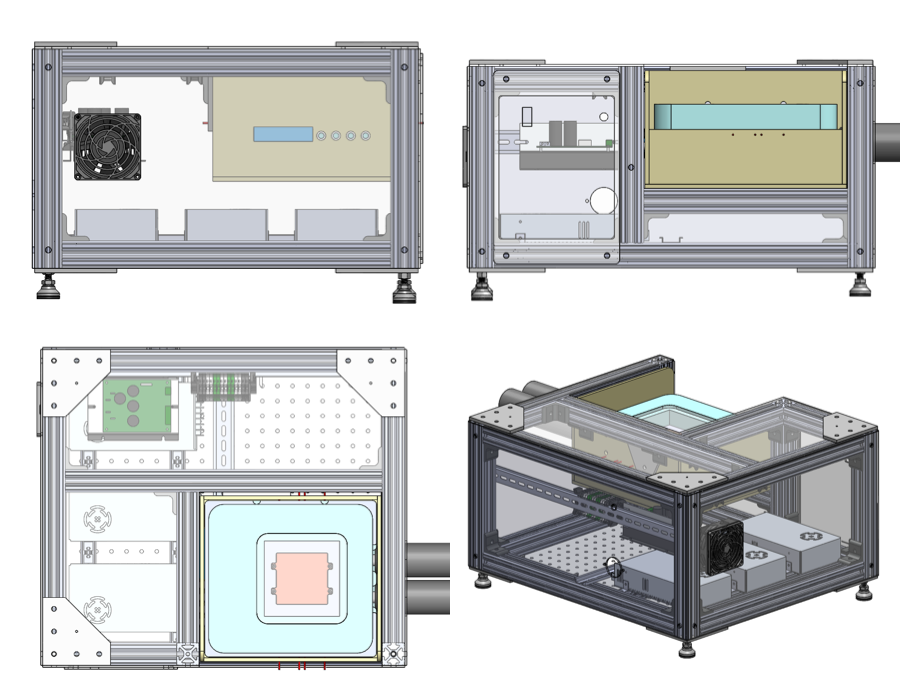

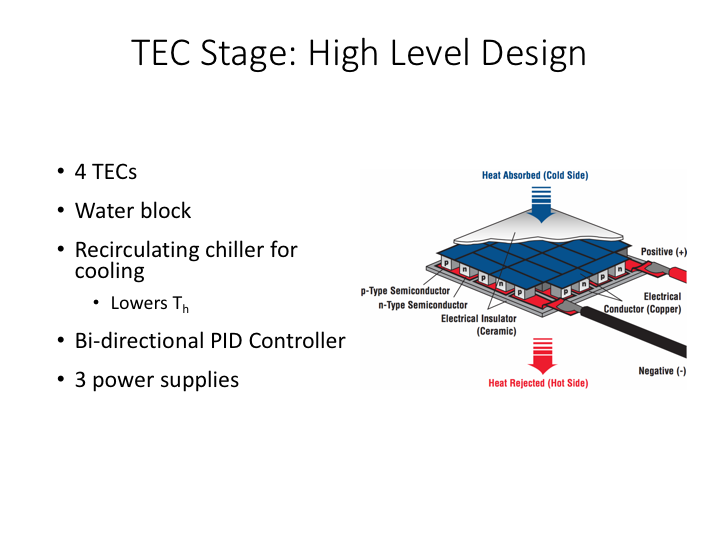

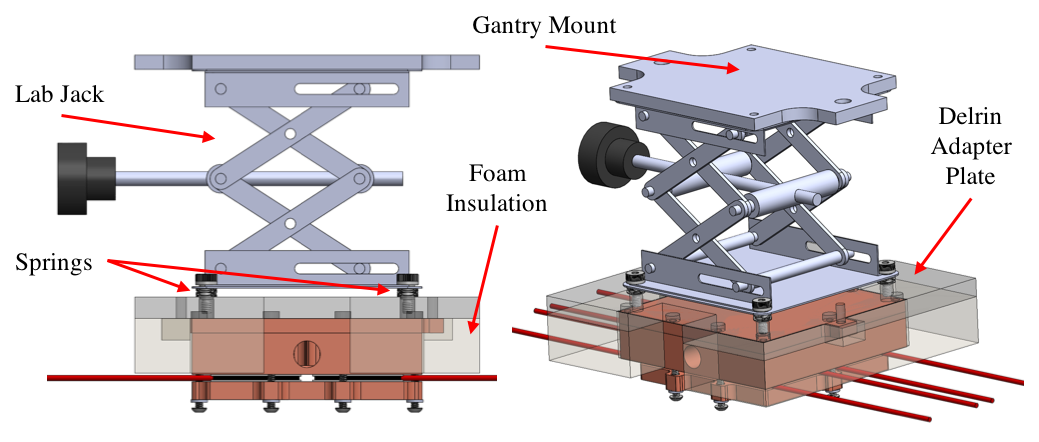

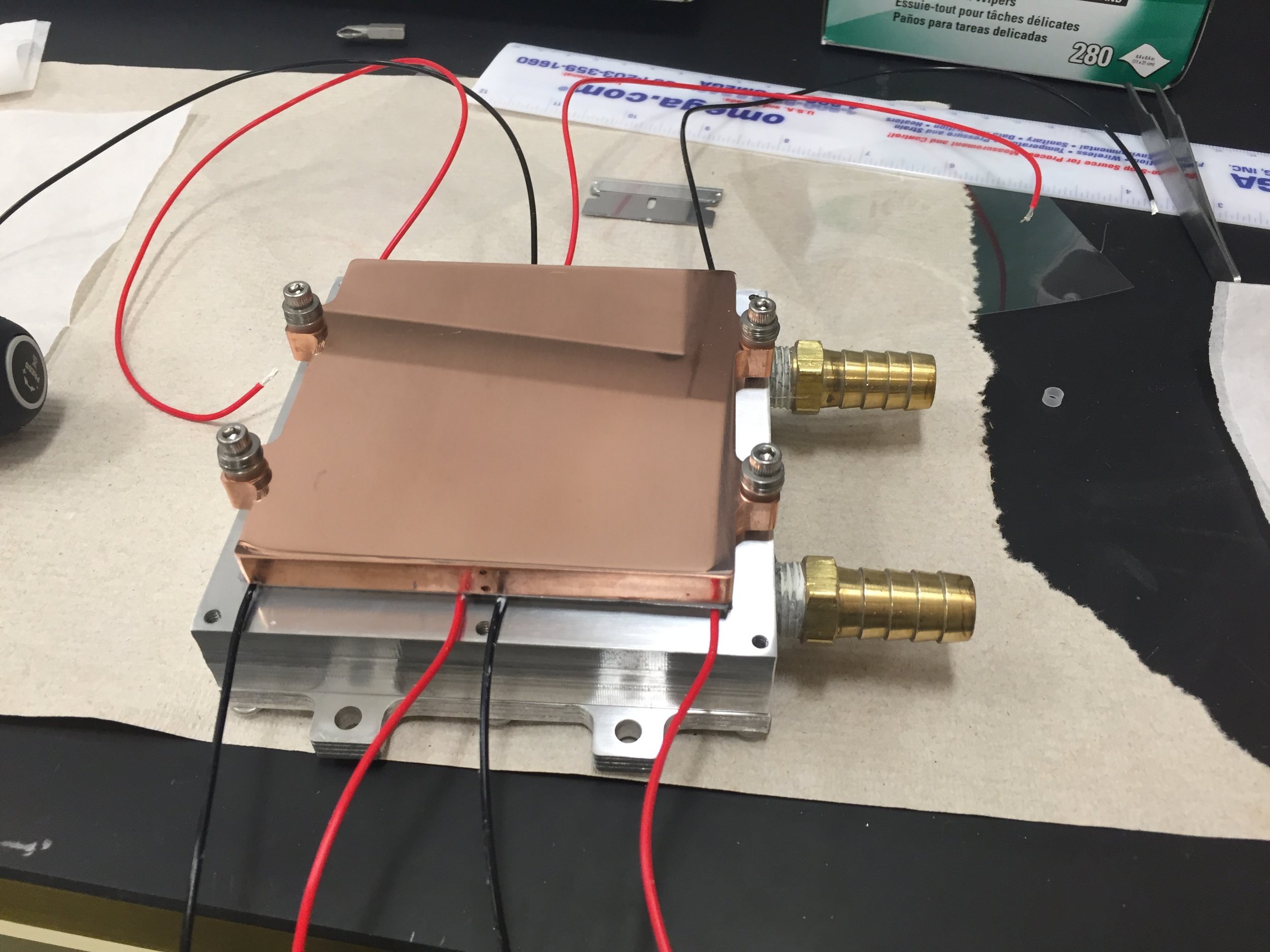

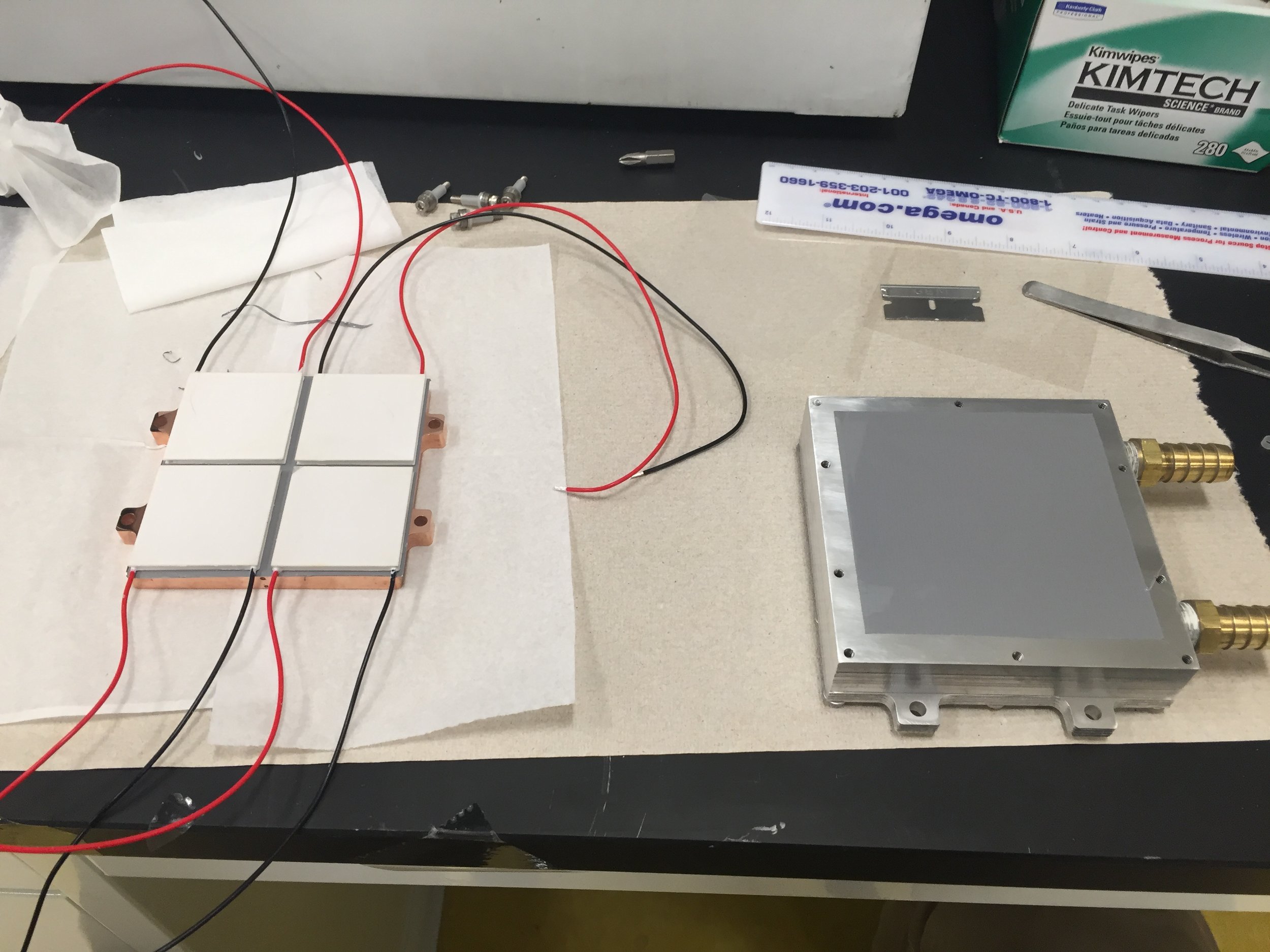

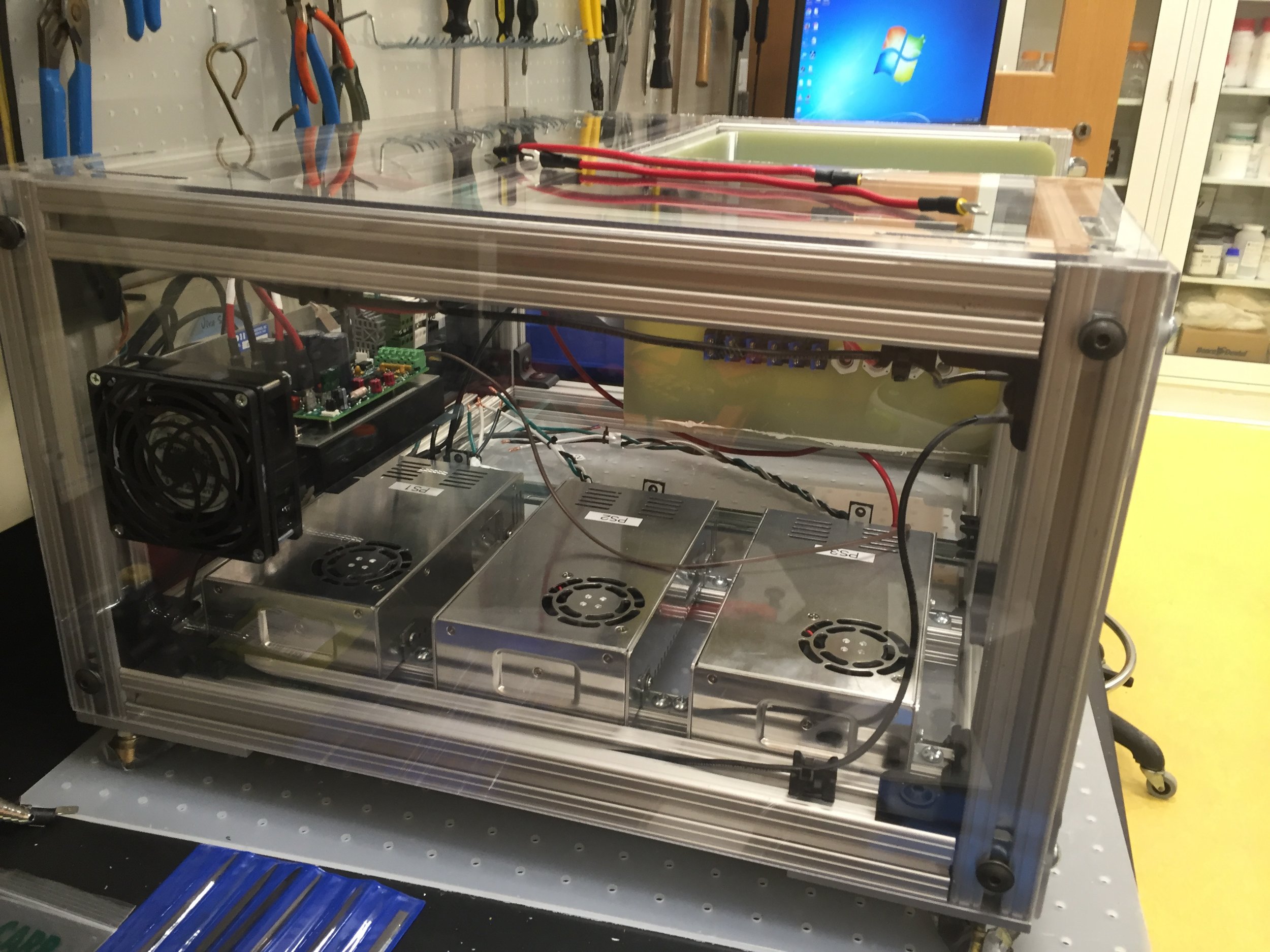

Thermoelectric Freezing Stage

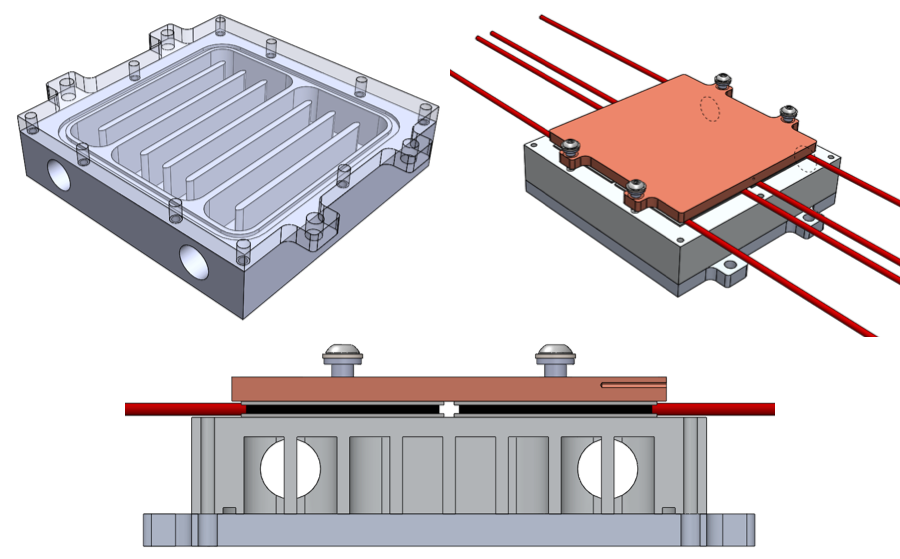

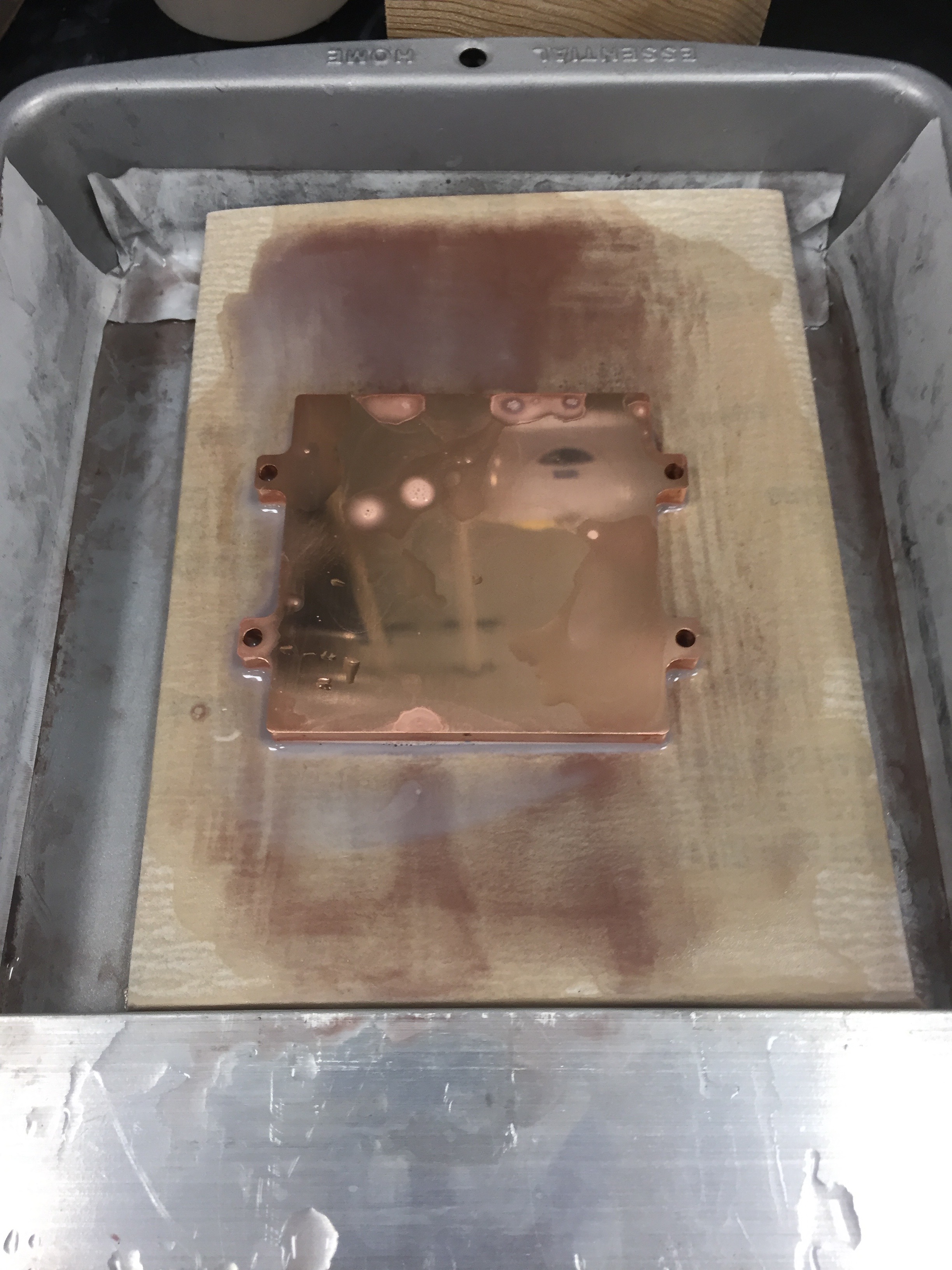

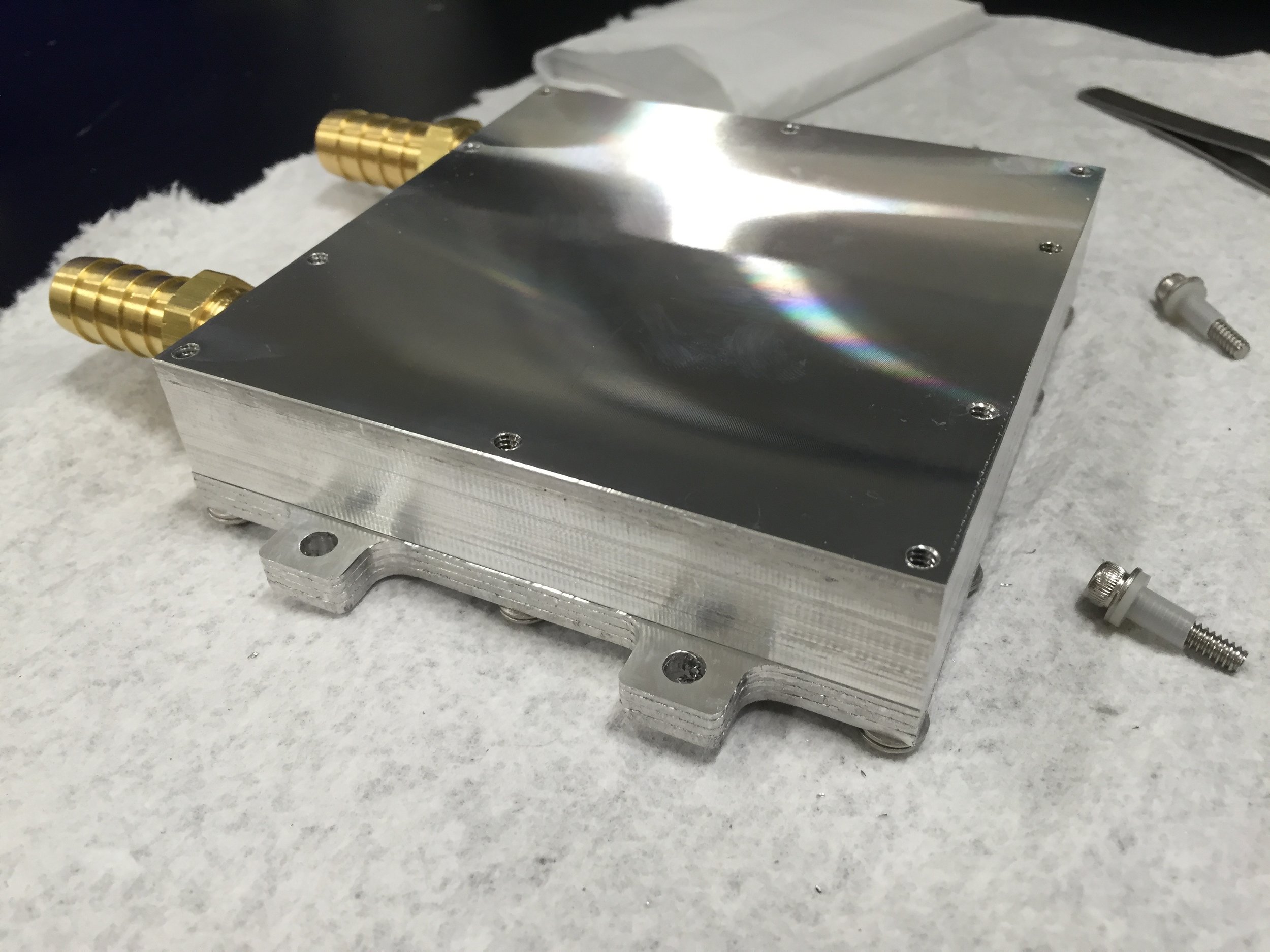

The overarching goal of the thermoelectric freezing stage was to demonstrate the feasibility of using thermoelectric cooling as an alternative to liquid nitrogen to provide cooling in order to freeze-cast samples. The device was designed specifically for the fabrication of sheet materials and improves on the current freeze casting process by addressing a number of constraints and inefficiencies identified in the Wegst Lab, namely the use of liquid nitrogen, limitations on sample sizes and shapes, and difficulty in mass producing samples.

Achieved

- Sheet freezing area of 80 x 80 mm

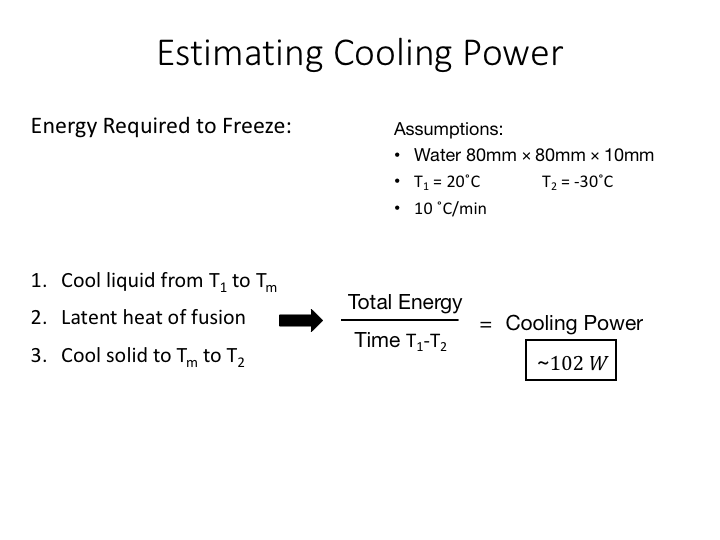

- Pass: 60˚C to < -30˚C

- Pass: 10˚C/min cooling rate down to -30 ˚C

- PID temperature control with programmable ramp / soak functions

Specifications and Requirements

Increase freezing area from 25 mm diameter cold finger

Temperature Range: 60˚C to < -30˚C

Cooling Rate: at least 10˚C/min cooling rate

Precise temperature control: fixed temperature & ramp / soak

Design

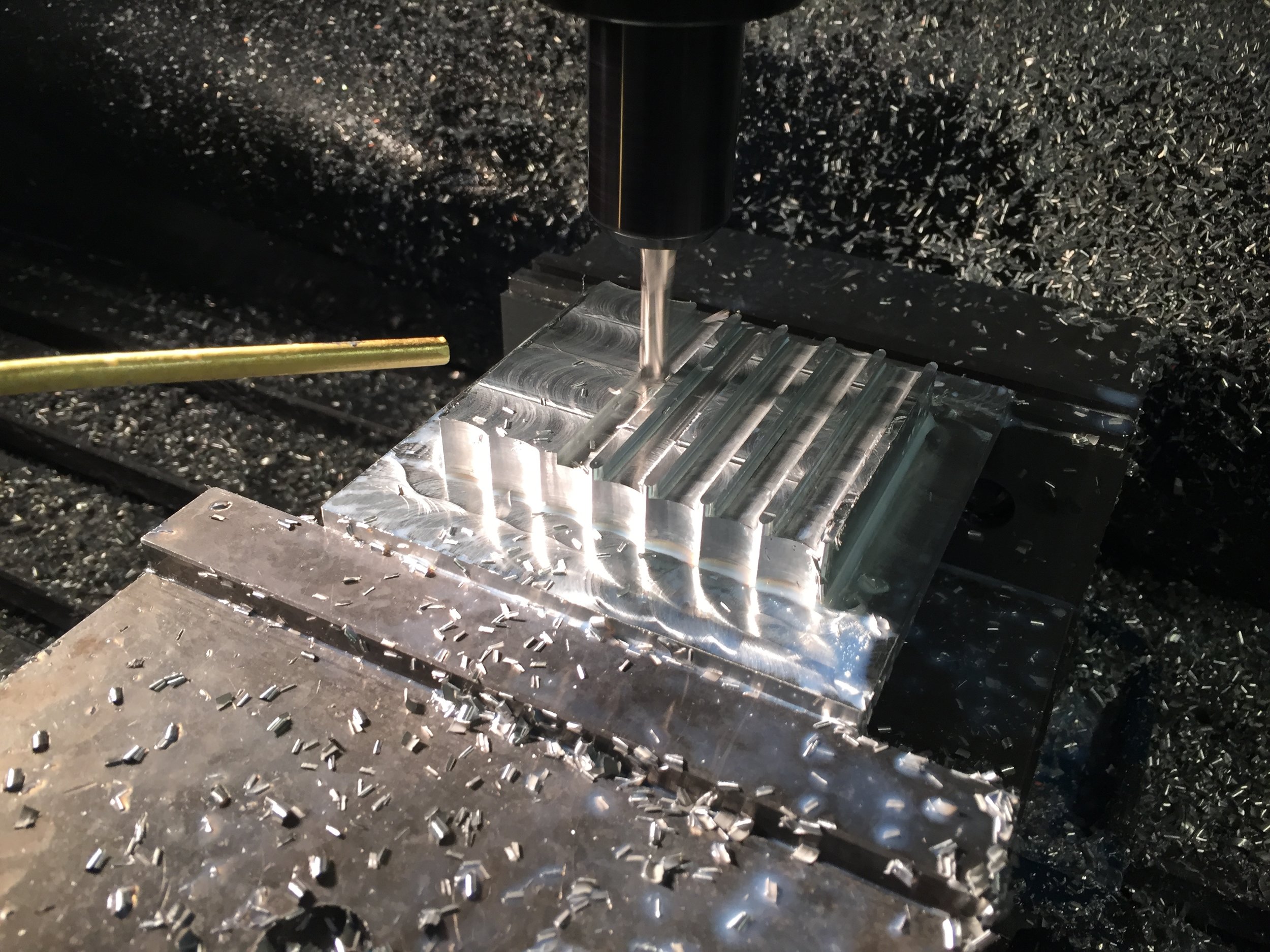

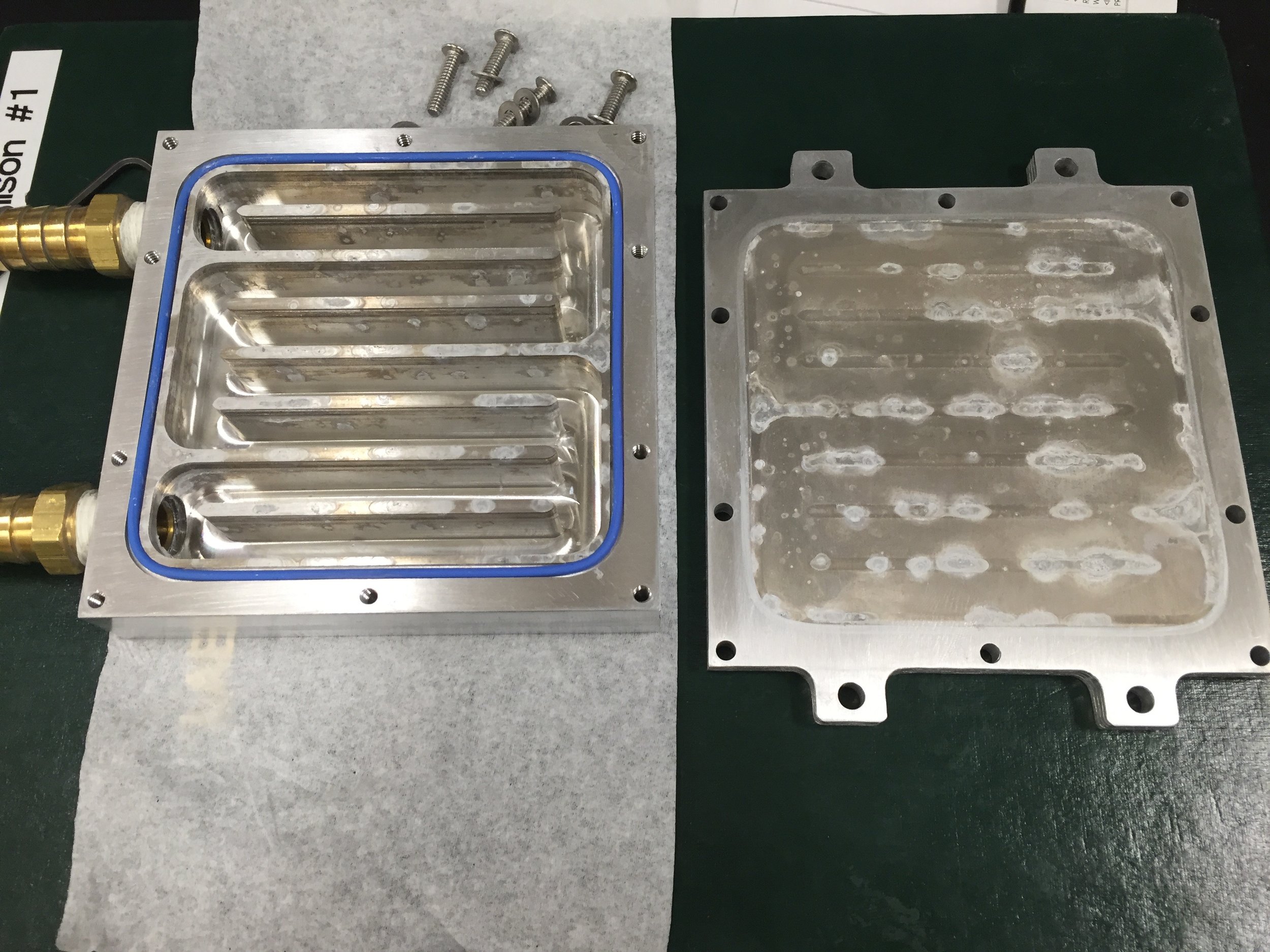

Build

Test